Search the whole station Products News

ICT & FCT INLINE testing

Project Case

As the world’s leading provider of automotive electronic solutions, customer B has always been deeply involved in the research and development and manufacturing of high-end automotive lighting systems. Facing the explosive demand of the new energy vehicle market, its traditional off-line manual testing mode encounters three challenges: the rising labor cost restricts the profit space, the lack of productivity flexibility limits the delivery capacity, and the risk of quality control consistency caused by manual detection fluctuations.

In order to break through the bottleneck of development, customer B took the lead in initiating intelligent transformation, and joined hands with PTI to build a whole-process automatic test system, realizing the digital closed loop of ICT circuit test, IC program burning and FCT function verification, and deploying a new test scheme driven by high-precision machine vision and AI algorithm.

Automatic code scanning (manual code scanning is supported) enables the product barcodes on the pallet to pass through the centralized code scanning platform, and uniformly writes the information corresponding to the pallet into the RIFD label to ensure one-to-one correspondence of products.

ICT Test

In-Circuit Test

ICT test system consists of PTI-2000B test organization, PTI-816S test master, PTI-816S test software platform and general industrial computer.

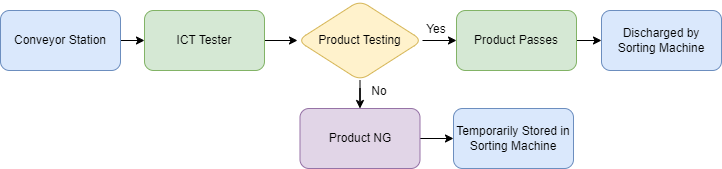

Schematic diagram of ICT test station is as follows:

ICT test items:

| Barcode acquisition |

| Impedance test |

| Open circuit test |

| Short circuit test |

| Electronic component testing |

| MES data transmission |

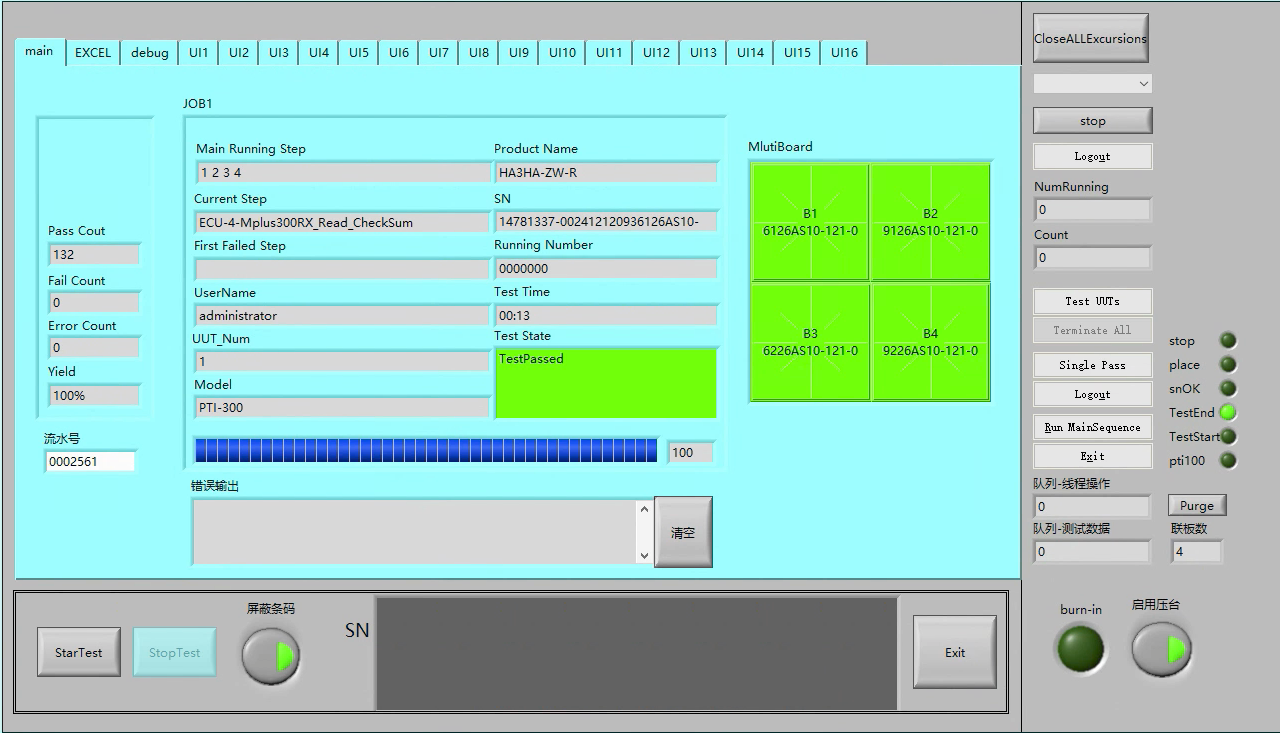

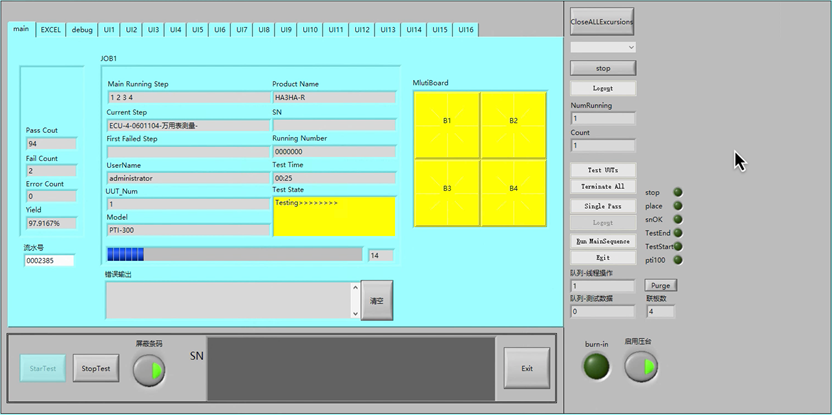

LABVIEW+TESTSTAND PTI-300

| Barcode acquisition |

| Power on the product |

| Multi-channel burning |

| View Checksum |

| MES data transmission |

Main interface of burning test

Main interface of burning test

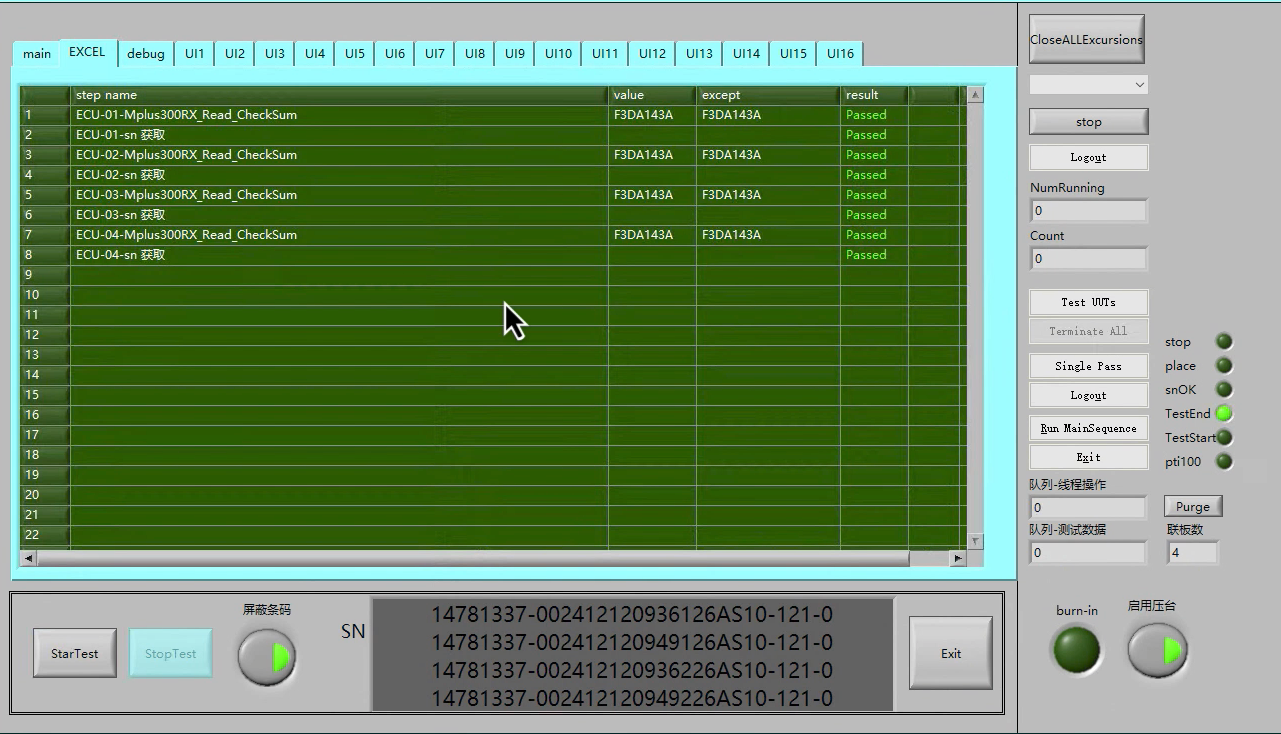

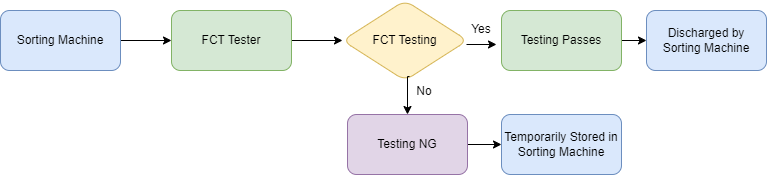

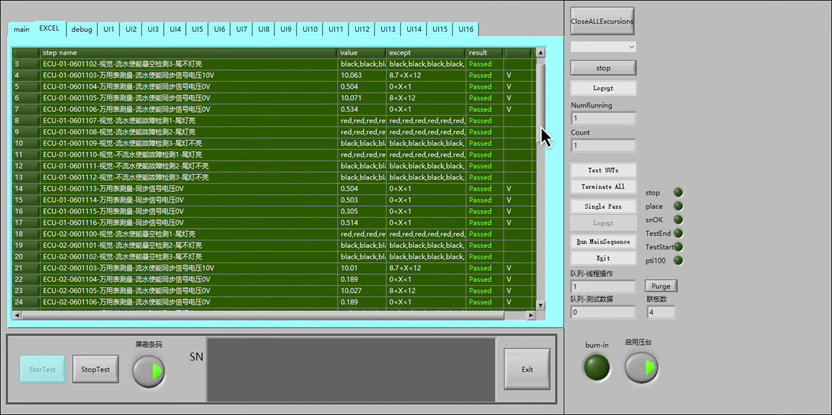

PTI-300 FCT Test interface

PTI-300 FCT Test item list

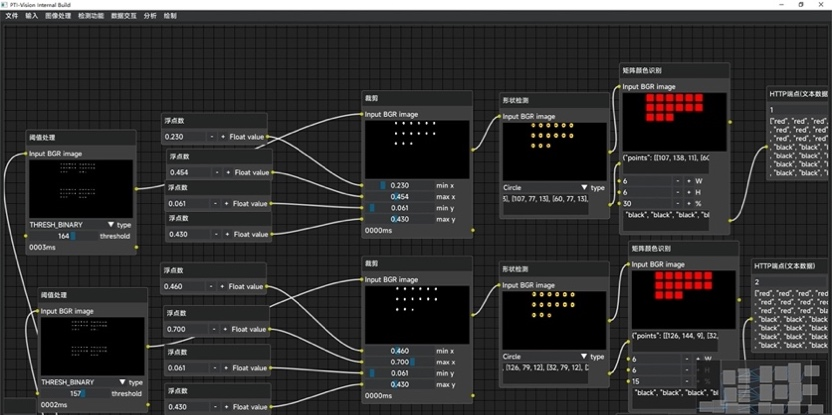

PTI-Vision Visual inspection interface

Test fixture

0

0